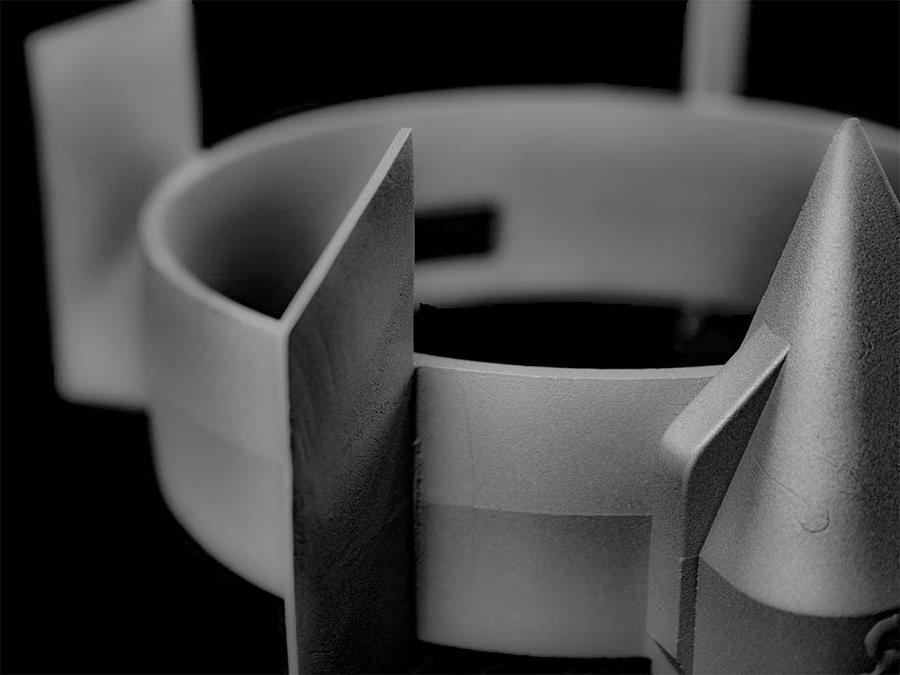

澳门新甫京网平台注册 manufactures high-precision investment castings, 加工零部件, and assemblies in both ferrous and non-ferrous alloys. Our AS9100 and NADCAP accredited processes deliver the highest 质量 castings for the most demanding applications.

Barron’s full-service manufacturing process includes everything from design for manufacturing to in-house casting, 数控加工, 非破坏性测试, 和焊接. Our vertically-integrated manufacturing process significantly reduces cost and lead times.

除了我们的 investment casting process,我们提供:

Barron's vertically integrated process offers more design and material flexibility than other metal forming techniques.

With more than 100 years of metal casting experience, the experts at 澳门新甫京网平台注册 investment casting foundry specialize in melting and pouring over 200 different types of ferrous and non-ferrous alloys, including high-strength 不锈钢, 铝, armor and nickel-based alloys. While Barron’s core business is metalcasting, it has evolved into a vertically integrated precision component manufacturer incorporating Industry 4.0. The production process starts with design for manufacturing and rapid prototyping to ensure efficiency and 质量. Post-casting capabilities include in-house machining, 涂装与装配, providing a completed subsystem component.

The emphasis we place on 质量 is demonstrated by our many certifications. We are NADCAP-certified for 非破坏性测试, including digital radiography and liquid penetrant testing, 我们还坚持 ISO 9001, AS9100、CMMC 2.0, as well as 质量 approvals from many major aerospace and defense OEM’s including 通用航空 and 波音公司.

Barron’s unparalleled expertise in investment casting sets our process apart from other investment casting foundries.

Barron uses the latest Solidification Modeling software to predict the outcome of a casting’s internal 质量 level before a part is ever made, significantly improving time-to-market and reducing development costs due to “trial and error” methods of process development.

Barron’s 5-axis robot ensures consistency in shell dipping, 涂层, and formation as well as enhanced efficiency in drying of ceramic shells. This results in more consistent high 质量 castings being delivered to our customers.

Barron operates three steel and two 铝 melting units, two ovens for wax burnout from the ceramic mold and four ovens for preheating ceramic shells. Redundant equipment ensures your castings will continue being processed, even if a piece of equipment breaks down.

Barron’s (MRP/ERP) software system provides operational intelligence allowing continuous improvement, 问责制, 质量, 实时跟踪, traceability and transparency throughout the investment casting process.

There are many benefits associated with investment casting, including:

许多不同的合金, 包括铝, 不锈钢, 碳钢, 工具钢, 灰口铸铁, nickel and cobalt alloys can be used in the investment casting process.

熔模铸造 produces complex parts with thin walls, superior dimensional accuracy, 表面光洁度, 内部稳健性.

Multi-piece fabrications can be converted into stronger and less expensive single-piece investment castings, reducing weight and lead times.

联系 澳门新甫京网平台注册 today to learn more about our process and capabilities, or to start your order.

Speak to one of our experts today to learn more about our custom casting solutions.